Grooved pipe fittings have gained significant attention in the construction and plumbing industries due to their efficiency. According to a recent market report by Global Industry Analysts, the demand for grooved pipe fittings is projected to grow by 5.2% annually. This increase highlights the innovative nature of these fittings, which enable faster and more reliable connections.

Industry expert John Smith, a leading figure in plumbing solutions, states, "Grooved pipe fittings simplify installation and enhance system integrity." This statement underlines the advantages that grooved fittings offer over traditional methods. Their designs allow for a quicker assembly, making them popular in both new constructions and retrofits.

However, challenges remain in the widespread adoption of grooved pipe fittings. Some professionals still cling to older methods, as they may be more familiar. Awareness and training are essential for maximizing the benefits of this technology. Nonetheless, grooved pipe fittings represent a significant evolution in fluid transport systems, promising an efficient future.

Grooved pipe fittings are essential components in modern piping systems. They simplify the connection of pipes and provide a reliable seal. These fittings feature grooves that allow for easy and secure assembly with the help of clamps. The installation process is straightforward, requiring minimal tools and time. This efficiency can reduce labor costs in large projects, saving up to 30% in installation compared to traditional methods, according to industry reports.

The characteristics of grooved pipe fittings include their durability and resistance to corrosion. Many grooved fittings are made from materials like carbon steel or stainless steel, ensuring longevity. Their design helps in absorbing vibrations, reducing the risk of leaks. According to the American Society of Mechanical Engineers (ASME), these fittings can withstand pressures exceeding 300 psi in many applications. Such performance makes them suitable for various industries, from oil and gas to fire protection systems.

While grooved systems offer many advantages, they also come with challenges. The initial cost can be higher than welded options. Additionally, improper installation can lead to failures. Regular inspections are crucial to maintaining their performance. Understanding these aspects is essential for those considering grooved fittings in their projects.

Grooved pipe fittings are critical in various applications, primarily in piping systems for HVAC, plumbing, and fire protection. These fittings ensure secure connections while allowing for easy assembly and disassembly. The materials used in grooved pipe fittings significantly affect their performance and longevity.

Common materials include carbon steel, stainless steel, and copper. Carbon steel is often favored for its strength and durability. It is 20% lighter than traditional welded fittings, which can simplify installation. Stainless steel is resistant to corrosion, making it ideal for environments with moisture and chemicals. According to industry reports, stainless steel fittings can last up to 50 years when properly maintained. Copper fittings, while less common, are valued for their antimicrobial properties and are often used in plumbing systems.

However, choosing the right material isn't always straightforward. Each material has its pros and cons. For instance, carbon steel may be cost-effective, but it is prone to rust without proper coatings. Stainless steel, on the other hand, is more expensive but offers excellent long-term value. Understanding these materials' unique characteristics ensures proper application in diverse environments, ultimately influencing the efficiency and safety of piping systems.

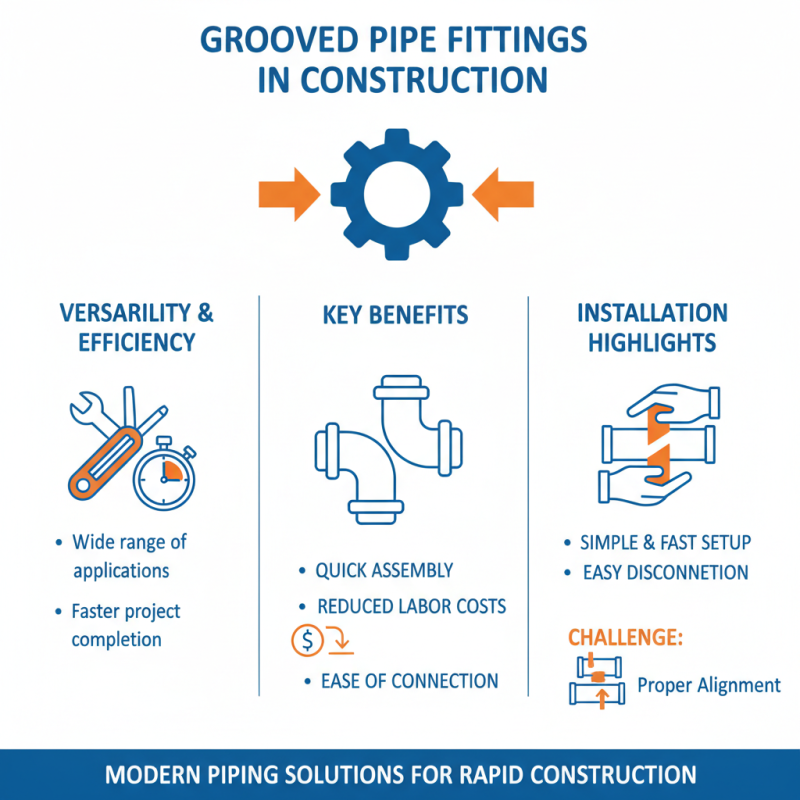

Grooved pipe fittings have gained significant traction across various industries for their versatility and efficiency. In the construction industry, these fittings simplify the installation process of piping systems. The design enables quick assembly, allowing such systems to be set up rapidly, which can save time and labor costs. Workers appreciate the ease of connection and disconnection. However, one challenge can arise from ensuring the proper alignment during installation, which may require adjustments.

In fire protection systems, grooved fittings play a critical role. They provide a secure connection in sprinkler systems and other fire suppression measures. The fittings can accommodate movement and thermal expansion, ensuring reliability. Yet, if not maintained properly, they can weaken over time. This highlights the need for regular inspections to mitigate any potential risks in these crucial applications.

Food and beverage industries also utilize grooved fittings extensively. These fittings support hygienic and efficient fluid transport. They allow for easy cleaning and maintenance, which is vital in such environments. Nonetheless, it is essential to choose the right materials to prevent contamination. This choice often leads to a balance between cost and safety, affecting overall system performance and longevity.

Grooved pipe fittings have gained popularity in various industries due to their unique advantages. Unlike traditional methods that often include welding or threading, grooved fittings utilize a simple interlocking mechanism. This can speed up installation significantly. Many professionals appreciate the ease of aligning pipes without extensive preparation.

Additionally, the use of grooved fittings can enhance the flexibility of a piping system. They allow for easier modifications and repairs. In tight spaces, this can be a lifesaver. A professional may find that grooved fittings reduce the need for special tools. This can save both time and money during installation.

**Tip: When working with grooved fittings, ensure the grooves are clean and free from debris. This prevents leaks and ensures a tight seal.**

One challenge could be the learning curve for seamless integration into existing systems. Some may struggle with understanding how to properly fit these components, leading to inaccuracies. Continuous training and practice can help address this. Embracing these fittings requires a shift in approach. However, the benefits often outweigh initial frustrations.

**Tip: To enhance compatibility, keep a close watch on manufacturer specifications for dimensions. Small discrepancies can lead to big problems.**

Grooved pipe fittings are widely used in plumbing and mechanical systems. These fittings feature grooves that allow for easy connection and disconnection. The installation process can be straightforward, but it requires attention to detail. Proper alignment is essential. Misalignment can lead to leaks.

To install a grooved pipe fitting, start by cutting the pipe to the desired length. The edges of the pipe should be smooth. Place the fitting onto the pipe, ensuring the grooves align. Use a clamp to secure the fitting in place. Over-tightening can cause damage. It’s crucial to regularly check the fittings for signs of wear.

Maintenance is often overlooked but is vital for longevity. Inspect the fittings at least once a year. Look for any corrosion or buildup around the grooves. Addressing issues early can prevent bigger problems down the line. Learning from mistakes is a part of this process. Each fitting has its quirks, and understanding these can lead to better installations.

This chart illustrates the evaluation criteria for grooved pipe fittings, including ease of installation, cost efficiency, maintenance frequency, durability, and versatility. The scores represent a percentage assessment of their performance in each category.