In the realm of industrial applications, selecting the right forged fittings is crucial. According to a recent industry report by Smith & Associates, the global demand for forged fittings is expected to grow at a rate of 5.2% annually. This growth indicates an increasing reliance on these components in various sectors, including oil and gas, construction, and manufacturing.

Mike Johnson, a well-known expert in the forged fittings industry, emphasizes the importance of choosing wisely. He states, "The right forged fitting can significantly enhance project efficiency and durability." While many may overlook the impact of forged fittings, the wrong choice can lead to costly failures. Proper material selection and compatibility are vital.

Moreover, not all manufacturers uphold the same quality standards. It's essential to review certifications and test results before making a purchase. Small details, such as fittings' pressure ratings and temperature tolerance, can make or break a project. In this competitive landscape, staying informed is key to making better decisions in procurement.

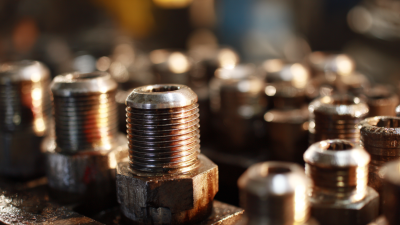

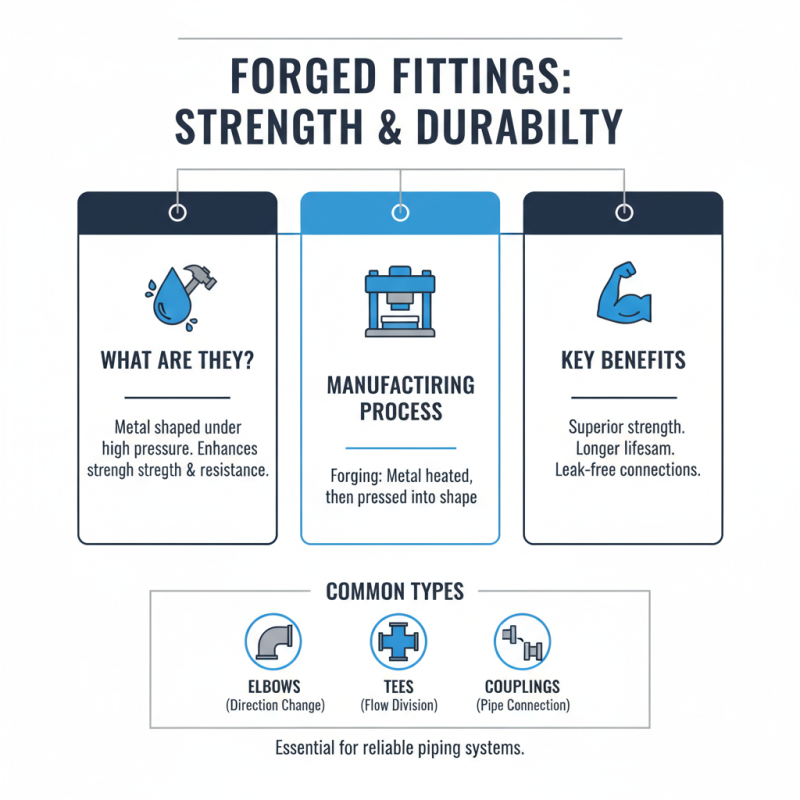

Forged fittings are essential components in various piping systems. They are manufactured through a process that shapes metal under high pressure. This process enhances the strength and durability of the fittings. Common types include elbows, tees, and couplings. Each type serves unique functions in different applications.

Understanding the applications is crucial for selecting the right fittings. For instance, high-pressure systems often require specific materials. Carbon steel is ideal for strength in demanding environments. However, it may not be suitable for corrosive substances. In such cases, stainless steel is preferred. Even small details, like the fitting's pressure rating, matter significantly.

Choosing the wrong fitting can lead to leaks or system failures. It’s essential to evaluate the temperature and pressure conditions. Some projects may require extensive testing. Be prepared for unexpected challenges. Reflecting on past choices helps in making informed decisions. In the end, each project demands a thoughtful approach to ensure safety and reliability.

Choosing the right forged fittings for your project involves several crucial factors. Material composition is key. Different projects require different materials, such as stainless steel or carbon steel. The environment also matters. For instance, if your project is outdoors, corrosion resistance becomes a priority. This impacts long-term durability.

Next, consider pressure ratings. High-pressure applications demand fittings that can withstand extreme conditions. It’s essential to check specifications thoroughly. Ignoring these details could lead to failures. Don’t forget the size. Ensure the fitting matches the pipe diameter perfectly. Mismatched sizes can result in leaks or reduced efficiency.

Finally, installation ease is often overlooked. Some designs are more user-friendly than others. Complex fittings may require special tools or skills. This could slow down your project. Reflect on these factors before making a choice. Some may realize too late that their selections were not ideal for the task. Balancing quality and practicality is essential.

When selecting forged fittings, understanding the types of materials is crucial. Common materials include carbon steel, stainless steel, and alloy steel. Among these, carbon steel is known for its strength and affordability. In fact, the global carbon steel market is projected to reach approximately $1 trillion by 2027, showing its high demand in various industries.

Stainless steel, which often contains chromium, is valued for its corrosion resistance. This makes it suitable for extreme environments. Data suggests that the stainless steel fittings market is expected to grow at a CAGR of 5.7% from 2021 to 2028. This growth highlights the significance of selecting the right material for your project needs.

Tip: Always consider environmental conditions when choosing a material. This can impact the lifespan of your fittings.

Alloy steel, on the other hand, offers enhanced wear resistance and is crucial in heavy-duty applications. However, it can be more expensive than its counterparts. Remember, not all projects require the most durable options. Sometimes, cost-efficiency is essential. Balancing performance and expense is key.

Tip: Evaluate the specific requirements of your project before making a decision. This will help ensure you select the most suitable fitting.

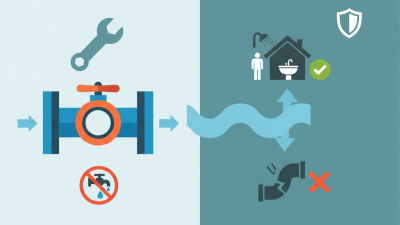

Choosing the right forged fittings for your project requires careful consideration of sizing and compatibility with existing systems. The wrong size fitting can lead to leaks, pressure loss, or inefficiencies. According to recent industry reports, nearly 30% of system failures are caused by improper fitting choices.

When assessing compatibility, check the dimensions, pressure ratings, and material types of your existing systems. Mismatched materials can lead to corrosion or mechanical failure. Always refer to compatibility charts and pressure ratings before selection.

Tips: Use a caliper for precise measurement. Ensure you include allowances for thermal expansion.

Another common mistake is overlooking the pipe standards. Some fittings may not connect due to varied manufacturing processes. Sizing should not only match the pipe diameter but accommodate types, such as schedule and wall thickness.

Tips: Cross-reference specifications with your project requirements. Order samples if possible to gauge fit and ease of installation.

When choosing forged fittings for a project, manufacturer quality is crucial. Investigating the standards they adhere to can reveal much about their reliability. Look for certifications that indicate compliance with industry standards. This often includes ISO certifications and other quality control measures. A lack of these might indicate potential issues.

Demand detailed information about materials used in the manufacturing process. High-quality steel should be free from defects and inconsistencies. Subpar materials can lead to failures, which may compromise the entire project. Evaluate the manufacturer’s track record. Check for reviews and case studies showcasing their work.

Not all manufacturers are equal. Be cautious of overly optimistic claims. Sometimes, companies present data that only highlights their strengths. It’s vital to look beyond the surface. Contact previous clients for their experiences. Honest feedback can guide you towards making a better choice. Stay vigilant and aim for the best quality available for your fitting needs.