When embarking on a construction project, selecting the right materials is crucial. Among these materials, the MS pipe stands out for its durability and versatility. Many professionals face challenges when choosing the best options for their specific needs. The right MS pipe can enhance the efficiency and longevity of your project.

Understanding the properties of MS pipes is vital. They can come in various grades and sizes, each suited for different applications. The market is flooded with options, making it easy to feel overwhelmed. You might wonder which type of MS pipe will truly meet your project's demands.

Consider the project scope and environment. For example, are you working on a water supply system or industrial piping? Each application requires different characteristics from your MS pipe. Reflecting on your choices is essential. Sometimes, the more affordable options might seem appealing, but they can lead to future issues. Therefore, take a moment to think about the long-term impact of your selection.

When selecting MS pipes for construction projects, various factors influence the decision. Thickness, diameter, and material quality are crucial parameters. According to industry reports, the right thickness can prevent future complications. Standard specifications vary; common thickness ranges from 2 to 10 mm. However, thicker pipes may be necessary for high-pressure applications.

One aspect often overlooked is corrosion resistance. Coating options can enhance durability. A recent study indicated that 30% of MS pipe failures are due to corrosion. Investing in better coatings can save costs in the long run. Look for pipes with additional protective layers.

Tips: Always consult with professionals. They can provide insights tailored to your specific needs. Consider the environmental factors at the project site. Weather conditions can affect pipe performance. Finally, ensure all materials meet industry standards. This reduces the risk of costly repairs later.

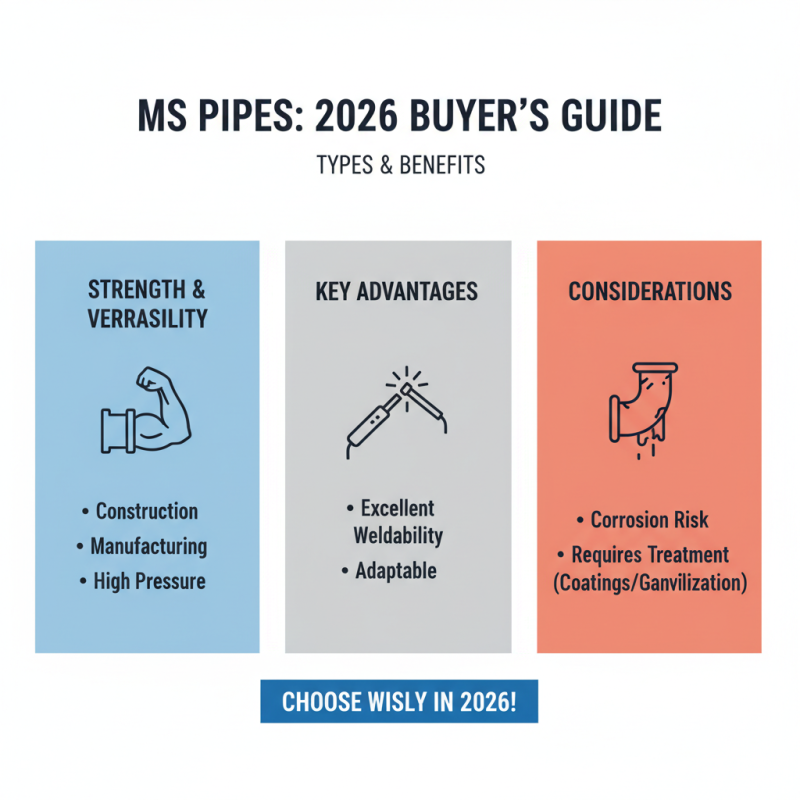

When choosing MS pipes in 2026, understanding their types is crucial. Mild steel pipes offer strength and versatility. They are commonly used in construction and manufacturing. These pipes can withstand high pressure, making them suitable for various applications. Their weldability is also a plus. However, they can corrode over time without proper treatment.

Seamless MS pipes are another option. They are made from solid steel and do not have joints. This construction gives them a smooth finish and higher pressure resistance. But seamless pipes can be more expensive. A buyer must weigh the cost against the benefits. Think about the specific needs of your project.

Then there are welded MS pipes. They are produced by welding together strips of steel. While they can be more affordable, they may not always meet high-pressure demands. Projects requiring durability might require re-evaluation here. Choosing the right type of MS pipe is not trivial. Each type has its pros and cons, and your requirements will determine the best fit.

When selecting MS pipes for your projects, there are various options available, each with its own strengths and weaknesses. A report from the International Energy Agency (IEA) indicates that mild steel pipes are widely preferred due to their high tensile strength and affordability. These pipes can handle high pressure, making them suitable for multiple applications. However, they can corrode over time, particularly in moist environments, which may not be ideal for projects requiring long-term durability.

Another popular option is galvanized MS pipes. These are coated to resist rust, extending their lifespan. According to recent market analysis, about 40% of construction projects favor galvanized pipes for plumbing and roofing. Yet, they are often heavier and can be more challenging to work with. Installation requires careful handling to prevent damage to the coating, which can defeat the purpose of choosing galvanized steel in the first place.

Stainless steel pipes are known for their high resistance to corrosion. They are particularly useful in industrial settings. However, they come at a premium price. A report from the American Institute of Steel Construction highlights that while the upfront investment is higher, the long-term savings on maintenance can be significant. Still, the decision must weigh short-term budget constraints against long-term operational efficiency.

This chart shows the cost per meter for various MS pipe options. Each type of pipe has its advantages and disadvantages in terms of cost, durability, and suitability for different projects.

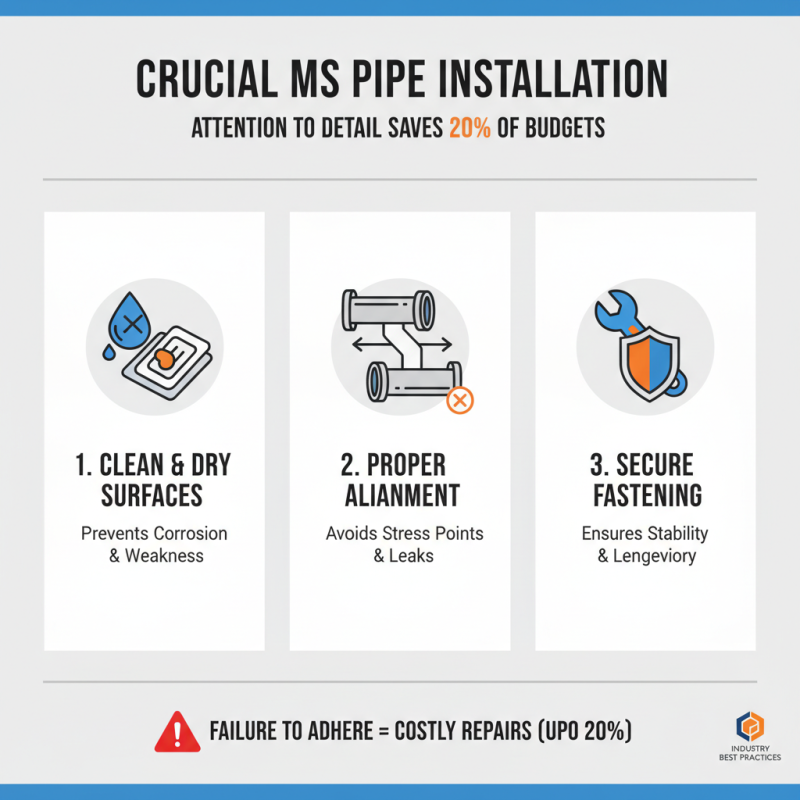

When it comes to MS pipe installation, attention to detail is crucial. According to industry reports, improper installation can lead to failures costing up to 20% of project budgets. Ensure the installation surfaces are clean and dry. Look for proper alignment; a misaligned pipe can create stress points.

Regular maintenance cannot be overlooked. It’s recommended to inspect MS pipes at least twice a year. Corrosion is a significant risk. In studies, nearly 25% of failures in MS pipes relate to corrosion issues. Apply protective coatings and check for any signs of wear or damage during inspections.

Tips: Always document your inspections and repairs. Keeping a log helps track issues and plan future maintenance. Additionally, using the right tools can make a huge difference. A good-quality wrench reduces the risk of damaging the pipe during assembly.

The MS pipe industry is evolving rapidly. Emerging trends shape how we approach projects. Sustainability is a key focus. MS pipes are now being made using eco-friendly methods. This reduces waste and energy consumption during production. More companies are adopting these practices.

Another trend is the rise of smart technologies. Sensors integrated into MS pipes can monitor conditions in real-time. This allows for proactive maintenance and reduces downtime. However, this technology may require upfront investment. Many projects may struggle with budget constraints.

**Tips for selecting MS pipes:** 1. Assess the specific needs of your project. Consider factors like pressure, temperature, and environment. 2. Always prioritize quality over cost. Lower prices can lead to more issues later. 3. Stay informed about new technologies. They can enhance efficiency and longevity.

As we look ahead, adaptability will be crucial. Projects must be flexible to incorporate changing standards and innovations. Moreover, teams should be ready to learn from past choices. Continuous improvement is key to success.

| Pipe Type | Diameter (mm) | Wall Thickness (mm) | Weight (kg/m) | Application Areas | Emerging Trends |

|---|---|---|---|---|---|

| MS Pipe A | 50 | 2.5 | 4.0 | Construction, Manufacturing | Lightweight and Corrosion Resistance |

| MS Pipe B | 75 | 3.0 | 6.3 | Oil & Gas, Plumbing | Sustainable Manufacturing Practices |

| MS Pipe C | 100 | 5.0 | 9.8 | Infrastructure, Vehicle Manufacturing | Automation in Production |

| MS Pipe D | 150 | 6.0 | 15.3 | Energy Sector, Transportation | Advanced Coating Technologies |