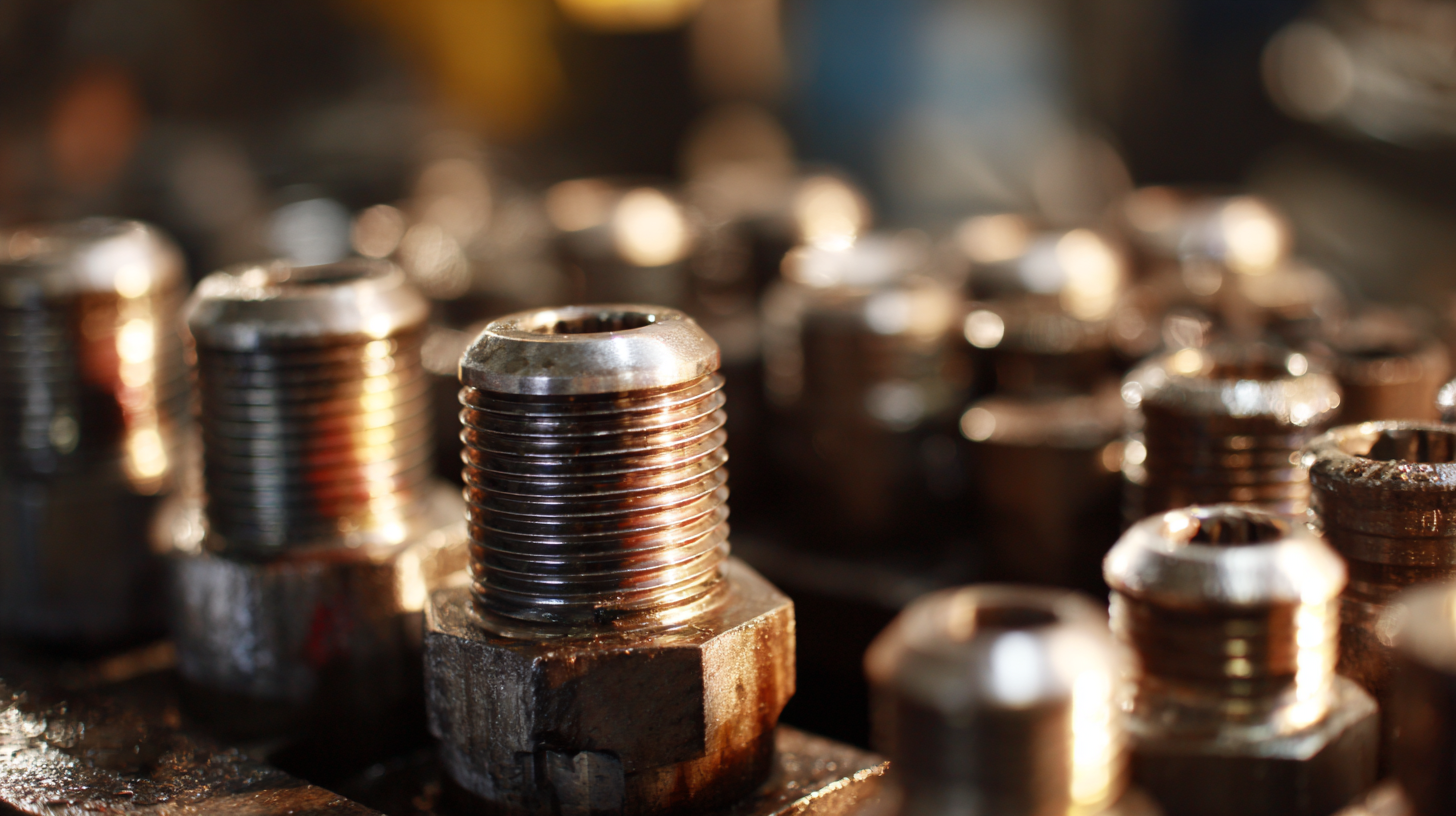

In the realm of modern industry, the significance of forged fittings cannot be overstated. These robust components, crafted through a process that enhances their strength and durability, play a pivotal role in a myriad of applications ranging from oil and gas to construction and shipbuilding. Their superior mechanical properties set forged fittings apart from their welded and cast counterparts, enabling them to withstand high pressure and extreme temperatures. This introduction seeks to delve into the myriad benefits and applications of forged fittings, highlighting their versatility and reliability in various industrial contexts. As industries continue to evolve and demand higher standards of safety and performance, understanding the critical role that forged fittings play will be essential for engineers and decision-makers alike. Whether it's for structural integrity or efficient fluid transport, the contribution of forged fittings remains invaluable in driving innovation and sustainability within the industrial sector.

Forged fittings are known for their exceptional strength and durability, making them invaluable in modern industrial applications. The ability of forged fittings to withstand high pressures and harsh environments enhances the overall reliability of piping systems. This is particularly crucial in industries such as oil and gas, chemicals, and water treatment, where safety and performance are paramount. The process of forging increases the density and structural integrity of metal components, resulting in fittings that can endure significant stress without failure.

Forged fittings are known for their exceptional strength and durability, making them invaluable in modern industrial applications. The ability of forged fittings to withstand high pressures and harsh environments enhances the overall reliability of piping systems. This is particularly crucial in industries such as oil and gas, chemicals, and water treatment, where safety and performance are paramount. The process of forging increases the density and structural integrity of metal components, resulting in fittings that can endure significant stress without failure.

Recent developments in materials and standards further underline the importance of choosing the right fittings for industrial applications. For example, ASTM's proposed specification for nylon 12 line pipe indicates a growing trend towards advanced materials that offer both strength and flexibility. This shift complements the use of forged fittings, as industries look to integrate high-performance components that can meet evolving regulatory and operational demands. As organizations aim to optimize their systems, the combination of forged fittings and innovative materials will likely play a pivotal role in enhancing the durability and efficiency of industrial processes.

Forged fittings are crucial components in several key industries, particularly in the energy, oil & gas, and chemical manufacturing sectors. In the oil and gas industry, these fittings are essential for ensuring secure and leak-free connections in pipeline systems that transport crude oil and natural gas. The U.S. Oil & Gas EPC market is experiencing significant growth, driven by increasing investments in infrastructure and the rising demand for energy. Forged fittings withstand high pressures and temperatures, making them ideal for such demanding applications.

In the chemical manufacturing sector, the need for reliability and safety is paramount. Forged fittings help mitigate risks associated with the transportation of hazardous materials. As the industry seeks to meet decarbonization targets, the introduction of new technologies and materials in forged fittings becomes a game-changer for both efficiency and compliance with environmental regulations.

Tips: When selecting forged fittings for specific applications, it is vital to consider factors such as material compatibility and pressure ratings. Additionally, ensuring proper installation and maintenance can significantly enhance the longevity and performance of these fittings in industrial settings. Regular evaluations can also help industries adapt to changing regulations and technological advancements efficiently.

When evaluating the cost-effectiveness of forged versus cast fittings, industry data reveals significant insights. According to a report by the American Society of Mechanical Engineers (ASME), forged fittings generally boast a lower production cost over time due to their superior strength and durability. These fittings are often made from high-grade steel allowing for thinner walls without sacrificing performance, which can lead to material savings of up to 30% compared to cast fittings. Additionally, the lower weight of forged fittings can reduce transportation costs, further enhancing their overall economic advantages.

In terms of lifecycle performance, a study published by the International Journal of Pressure Vessels and Piping highlighted that forged fittings experience a 25% lower failure rate than their cast counterparts. This reliability translates to reduced maintenance expenses and downtime for industrial operations. Furthermore, industries that require high-performance applications, such as oil and gas, often prefer forged fittings, as they can handle extreme pressures and temperatures more effectively. As industrial plants weigh the initial costs against long-term operational efficiency, the preference for forged fittings becomes increasingly evident, reinforcing their place in modern manufacturing and construction practices.

| Fitting Type | Material Cost ($/kg) | Production Cost ($/unit) | Strength (MPa) | Application Suitability | Average Lifespan (Years) |

|---|---|---|---|---|---|

| Forged Fittings | 6.50 | 15.00 | 600 | High-pressure systems, oil and gas | 30 |

| Cast Fittings | 4.00 | 10.00 | 300 | Low-pressure systems, plumbing | 20 |

When it comes to the installation of forged fittings, ensuring safety and efficiency is paramount. According to a report by the American Society for Testing and Materials (ASTM), improperly installed fittings can lead to significant safety risks, including pressure leaks and potential machinery failures. The correct installation of forged fittings involves following precise torque specifications as outlined by the manufacturer. For example, the ASME B16.5 standard provides guidance on the torque values that ensure the integrity of the connection, which is crucial in high-pressure applications prevalent in industries like oil and gas, where the stakes are especially high.

Another key aspect to consider is the selection of compatible materials. A study by the National Association of Corrosion Engineers (NACE) highlights that the mismatch between materials can lead to galvanic corrosion, compromising the joint over time. Therefore, it is recommended to adhere to guidelines that specify not just the fittings’ material composition but also the pipe materials they should be paired with. Additionally, maintaining an appropriate temperature range during installation is essential to mitigate the risks associated with thermal expansion, which can ultimately enhance the longevity and reliability of forged fittings in various industrial applications.

The forged fittings industry is poised for significant evolution, with innovations and market growth projected to flourish through 2030. Advances in manufacturing processes, such as the adoption of automation and additive manufacturing techniques, are expected to enhance the precision and durability of forged fittings. These improvements will not only optimize their performance in high-pressure environments but also reduce production costs, making them more accessible for a broader range of applications.

Additionally, the growth of sectors like oil and gas, construction, and renewable energy is likely to drive demand for forged fittings. As industries seek more efficient and reliable components to support their infrastructure, the need for advanced forged fittings will increase.

Sustainability will also play a crucial role, with manufacturers focusing on eco-friendly materials and processes. This trend towards sustainability is anticipated to not only cater to the rising environmental awareness but also align with global efforts to meet stricter regulatory requirements. Overall, the future of forged fittings is bright, marked by innovation and a robust market trajectory.