In the realm of industrial applications, the significance of high-quality fittings and valves cannot be overstated. As John Smith, a renowned expert in the fittings and valves industry, once said, "Choosing the right fittings and valves is critical for ensuring system reliability and efficiency." The year 2026 presents a pivotal moment for innovations in these components, pushing boundaries further than ever.

Fittings and valves play a key role in optimizing operational performance. They dictate the flow of liquids and gases within various systems. Poor choices can lead to leaks or system failures. The market is expanding, with new materials and technologies emerging. This progress demands a critical look at what truly enhances efficiency.

As experts continue to evaluate new solutions, some challenges remain. Not all fittings and valves meet the highest standards. Manufacturers often prioritize cost over quality. This creates performance gaps that can significantly impact operations. Acknowledging these issues is essential in striving for optimal performance.

In modern applications, fittings and valves play a crucial role in optimizing performance and efficiency. These components connect pipes and manage fluid flow. They are vital in various industries, including manufacturing, plumbing, and chemical processing. Choosing the right fittings and valves can significantly affect system reliability and energy consumption.

Many professionals focus on materials and designs. Yet, overlooking small details can lead to inefficiencies. For instance, mismatched fittings can cause leaks or pressure drops. Regular maintenance is essential to ensure these parts function correctly.

Innovation is ongoing. New materials and technologies continuously improve fittings and valves. However, understanding the specific needs of each application remains challenging. Engineers often struggle to balance cost with performance. This gap can hinder advancements and require constant reassessment.

When selecting fittings and valves for 2026, specific characteristics play a crucial role. High-performance fittings should ensure a tight seal to prevent leaks. Material selection is vital; corrosion-resistant materials can enhance longevity and reliability. Keep in mind that even the best materials can wear over time. Regular inspections help catch any early signs of wear.

Another key characteristic is compatibility with various fluids. Not every fitting or valve works well with all substances. Testing in your specific environment can reveal potential issues. Optimal performance often requires balancing pressure ratings and flow rates. Sometimes, a fitting may exceed pressure ratings but fail to meet flow needs.

Efficiency matters as well. Energy loss can occur if the right fittings aren’t used. Fluid dynamics should be considered when designing a system. Sometimes the best solution means using multiple fittings creatively. It’s crucial to evaluate overall system performance regularly. Each component should be assessed within the big picture of efficiency and effectiveness. Adjustments may be needed based on findings, prompting a continuous cycle of improvement.

In 2026, selecting the right fittings and valves is crucial. Materials play a significant role in performance. Stainless steel and brass remain popular choices, offering durability and resistance to corrosion. However, there is a growing push for advanced composites. These materials can provide weight savings and enhance flexibility.

Technological advancements are reshaping this sector. For instance, 3D printing allows for customized designs. This innovation can lead to more efficient flow paths and better energy conservation. Yet, the technology is still evolving. There are questions about long-term reliability. Companies must balance innovation with conventional materials.

Efficiency also relies on smart design. Engineers are learning from past mistakes. Many fittings have fallen short in terms of maintenance. Simplified designs with fewer components can improve serviceability. It’s essential to consider both efficiency and ease of use. As the industry grows, a critical evaluation of materials and technologies will shape future decisions.

| Type | Material | Efficiency Rating | Temperature Range (°C) | Pressure Rating (bar) |

|---|---|---|---|---|

| Ball Valve | Stainless Steel | 90% | -20 to 200 | 16 |

| Gate Valve | Bronze | 85% | -20 to 150 | 20 |

| Butterfly Valve | PVC | 80% | 0 to 60 | 10 |

| Check Valve | Cast Iron | 75% | -10 to 120 | 25 |

| Plug Valve | Nickel Alloy | 88% | -30 to 250 | 30 |

Proper installation and maintenance of fittings is crucial for optimal performance. Each fitting must match the pipe size and type. Tools should be well-calibrated.

Tightening connections often requires specific torque settings. Overtightening can damage threads, leading to leaks. Risk versus reward must be considered.

Over time, even the best materials can fail if not monitored properly.

Regular inspections can identify issues before they escalate. Look for visible wear, rust, or deformation. Clean fittings regularly to prevent blockages. Use lubricants as needed, but ensure they are compatible with the material. Document any maintenance performed, which can highlight patterns of deterioration.

Fittings are often forgotten until a problem arises. It’s vital to keep an eye on them. Develop a routine for checking fittings every few months. Small reminders can help maintain efficiency. Every fitting has its limits, and knowledge of these can prevent future issues.

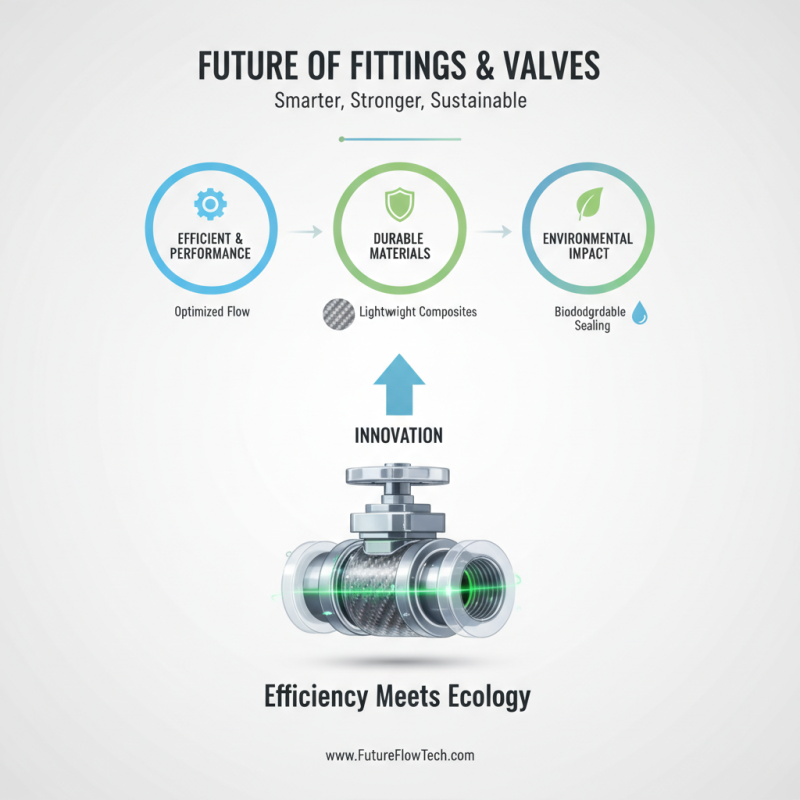

The future of fittings and valves is shaping up to be more efficient and performance-driven. Innovations are steering designers toward materials that enhance durability and minimize environmental impact. Lightweight composites are gaining traction, promising improved efficiency without sacrificing strength. As industries focus on sustainability, biodegradable options for sealing and sealing systems are becoming essential.

Advanced technology is also transforming how fittings and valves operate. Smart sensors can monitor pressure and flow in real-time. This capability helps identify issues before they escalate. Performance metrics have never been clearer. Yet, manufacturers face the challenge of balancing innovation with cost. The push for cutting-edge technology often leads to increased prices, putting pressure on small to medium enterprises.

Moreover, energy efficiency remains a pressing concern. Continuous advances are needed to ensure that fittings and valves consume less energy during operation. While some companies are making strides, there is a long way to go. Collaboration across industries may become vital for pushing these boundaries. Finding common ground might be difficult but essential for better standards.